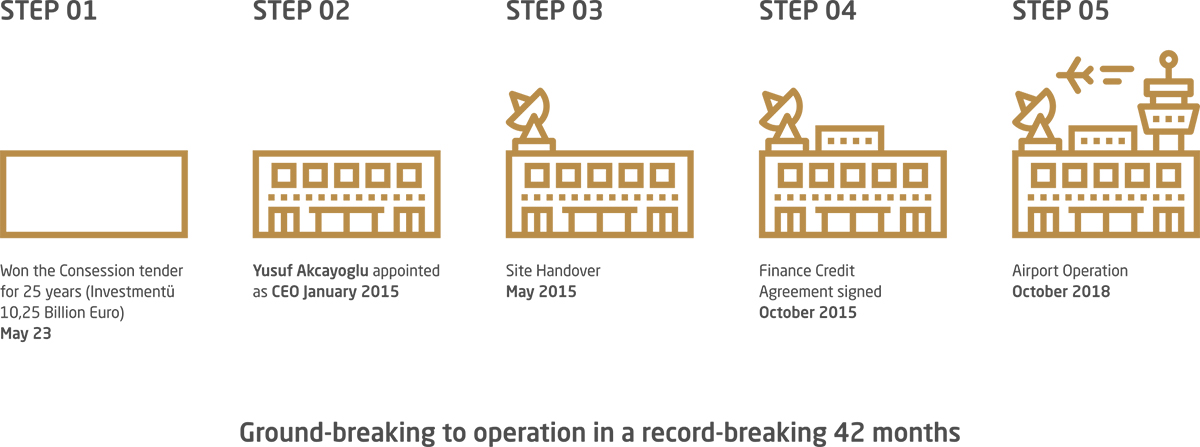

With the transfer of CEO Yusuf Akcayoglu to the project, the Master plan was finalized, Project Core Team was established, Project Finance Closure was achieved and construction kicked-off immediately.

Senior Manager, Project Management and Expert Technical Staff Organization (with similar airport projects experience, fast-track Build-Operate-Transfer (BOT) culture and design & build background) were brought together by the CEO.

The open office concept has been applied in the main construction site office and different disciplines such as Design, Construction, MEP, IT, SAS, BIM, Contracts & Commercial, Financial & Administrative affairs, Infrastructure, Environment and Sustainability, QA/QC, HSE, Human Resources, Procurement & Logistics, Corporate Communications, Management are positioned side by side in an assembly line logic. Through the assembly line approach, maximum connectivity between the disciplines has been achieved.

This mega project is hands-on and closely monitored with weekly, multi-disciplinary, coordination meetings under the leadership of Yusuf Akcayoglu.

.jpg)

Undoubtedly, the most important point is that all these works’ design & construction is done simultaneously with the maximum resource loading approach. Design is progressively driven according to the priority of critical path activities to commence earliest.

Project success is granted thanks to;

- • on-time establishment of the expert project team,

- • the quick initiation of the design processes,

- • the preparation of the specifications,

- • preparation of tender packages and tender process ,

- • procurement in line with work schedule and critical path and

- • Early start of excavation works with box-cut method applied for the terminal building and other important facilities such as Utility Center, ATC Tower, GIS and Datacenter.

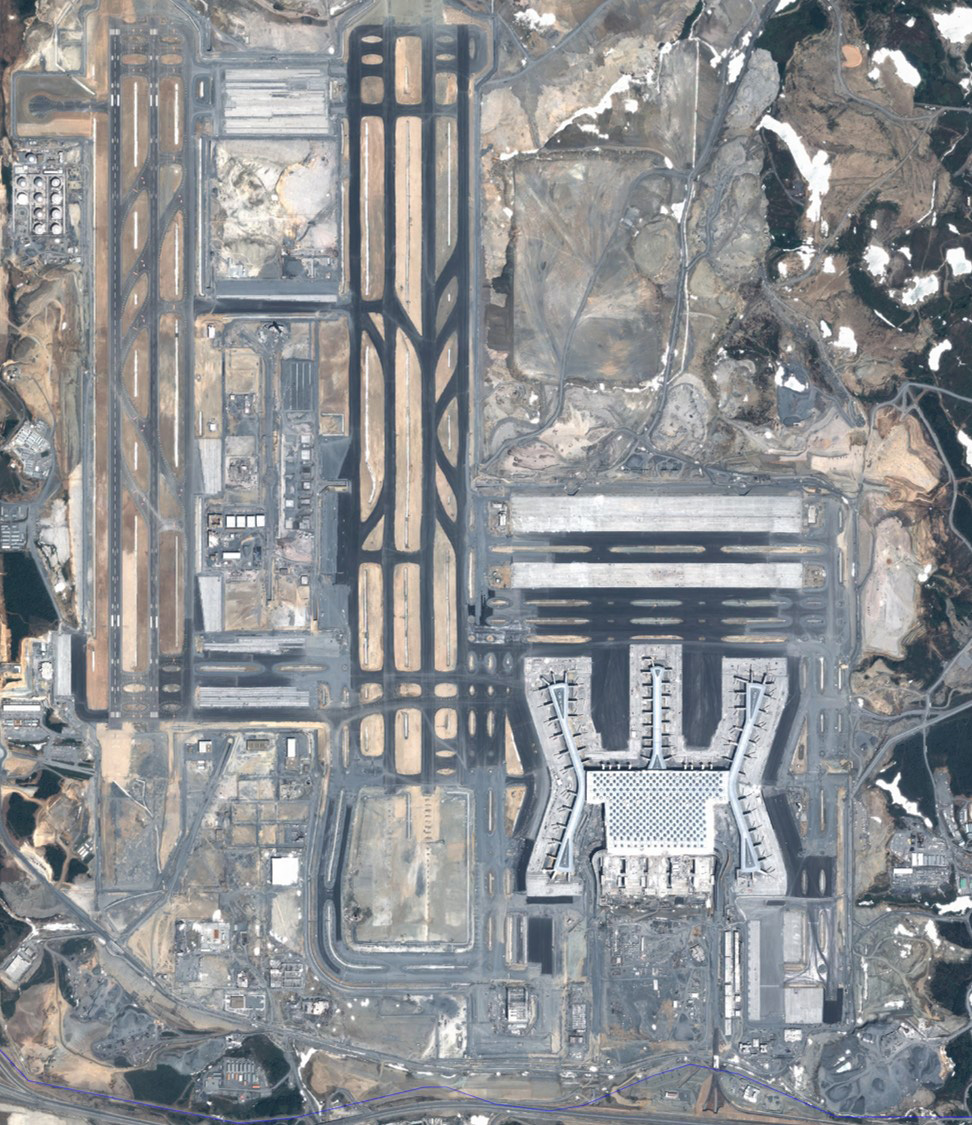

The mega project, spanning on 76 mio sqm land area, consists of four construction stages. Akcayoglu’s work scope was to build the initial phase (Phase1a) which represented almost %80 of whole works and can handle up to 120 mio PPA. The first stage of construction is finished within 42 months.

.jpg)

The Air Traffic Control (ATC) tower, which became one of Istanbul's iconic architecture symbols, was designed by famous Italian designer Pininfarina. The ATC tower was selected through a design competition and Yusuf Akcayoglu's direct involvement / decision in favor of the Pininfarina design.

The first stage consists of the main terminal which has an annual passenger capacity of 90 million and encompasses an area of 1,4 mio sqm – making it the world's largest airport terminal building under a single roof.

.JPG)

The airport currently has one terminal in service for domestic and international flights and four runways that are currently in operation. The two 17/35 runways are both 4,100 metres (13,451 feet) long, while the 16/34 runways are both 3,750 metres (12,303 feet) long. Runways 17L/35R and 16R/34L are 60 metres (197 feet) wide, while 17R/35L and 16L/34R are 45 metres (148 feet) wide. All runway surfaces are asphalt.

There are two pairs of parallel runways connected to eight parallel taxiways to the west of the main terminal, approximately 4,000,000 m2 (43,000,000 sq ft) of apron space, and an multi-storey car-park with a capacity of 18,000 vehicles. In addition, the airport features technical blocks for repairs, maintenance, and fueling, as well as an air traffic control tower, hangars for cargo and a fuel port. Several other services are also in operation, including hospitals, frequent-flyer and VIP lounges, prayer rooms, convention centers, and hotels.

Phase-1a of the project includes one mega terminal serving domestic and international flights over 143 Passenger Boarding Bridges and four runways including auxiliaries. Runway-1(34L/17R) is 3.750m long and 60 meters wide. Runway-2 (36R/18L)is 4.100m long and 60 meters wide. Each of the two runways also has one auxiliary runway with 45 meters width. All runway and taxiway surfaces are paved as asphalt. There is approximately 4,000,000 m2 of apron space (built as concrete pavement).

Multi-storey car-park is of 700.000 sqm floor area and has a capacity of 18.000 vehicles. In addition, the airport features ancillary buildings for maintenance, storage, snow removal equipment , waste collection , security ,customs and fueling, as well as an air traffic control tower, hangars for cargo and a jetty port facility.

Several other services are also set in operation, including hospitals, frequent-flyer and VIP lounges, prayer rooms, convention centers, hotels and a separate VIP terminal.

.jpg)

..

.jpg)

..

.JPG)

..

.jpg)

..

.jpg)

- A large and comprehensive organization has been established in order to realize the project.

- In the organization and project management process, an integrated and comprehensive management structure that integrates different disciplines has been established and the open office standard has been used.

- Occupational safety training was given to more than 200 thousand people in 24 different topics.

- With 50 doctors and 120 healthcare professionals, a health system with a capacity of 800 people/day was provided. 1 hospital and 10 different health points, and 5 ambulances were kept ready at all times.

- A total of 28,000 employees were provided with accommodation and laundry services in IGA camps, and cleaning services were provided in the camps and construction sites with the help of 1,100 cleaning personnel.

- Speed and traffic control / management was carried out with on-site radar + GPS monitoring.

- Daily transportation of 28,000 people inside and outside the field was provided with 600 service vehicles.

- Total volume of poured concrete exceeded 5 million cubic meters.

- More than 600.000 tons of reinforcement steel was used.

- More than 110.000 tons of structural steel elements were used.

Site Area |

76 million m², Total Build up area: ~2,600,000 m² |

Construction Quantities |

|

Duration |

42 Months Design & Build |

PERSONNEL (as of Oct 2017) |

|

|---|---|

| ENGINEER / ARCHITECT / ADMIN | 4,100 |

| WORKERS | 37,400 |

| TOTAL(16 different nationalities) | 41,500 |

Heavy Equipment Type |

# of Units |

|---|---|

| Heavy Duty Trucks | 2.200 |

| Excavators | 255 |

| Graders | 65 |

| Rollers | 158 |

| Dozers | 116 |

| Concrete Mixer Trucks | 120 |

| Concrete Pump Trucks | 42 |

| Tower Cranes | 95 |

| Mobile Cranes | 356 |

| TOTAL | 3.400 |

Factories & Plants |

|

|---|---|

| Concrete Plants | 7 units |

| Asphalt Batching Plant | 6 units |

| Precast Concrete Factory | 5 units |

| Structural Steel Factories | 5 units |

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.JPG)

.JPG)

.jpg)

.jpg)

.JPG)

.JPG)

.jpg)

.jpg)

.JPG)

.JPG)

.jpg)

.jpg)

.JPG)

.JPG)

.jpg)

.jpg)

.jpg)

.jpg)

.JPG)

.JPG)

.JPG)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)